Think

“Think” reflects our philosophy. Our hyper-focused approach to solutions. Think Different Print.

ConnectDifferent

In a market of lookalikes, our customer-first approach is our distinction. It’s our obsession. Be Different.

Connect“Print” embodies the fusion of a technology company with state-of-the-art machinery and bespoke software, ensuring unparalleled speed, quality, and efficiency.

Connectbetter.

Faster.

Cheaper.

Welcome to The Future: Better, Faster, Cheaper

Welcome to a new era of printing, where it’s not just about ink and paper but about speed, quality, and cost-effectiveness—ultimately about delivering real value.

We are establishing a new standard: a world where labels are dispatched within 48 hours at the lowest prices in the industry. In this world, companies can order only what they need to fulfill current production schedules, thereby minimizing waste, energy consumption, and emissions.

We have redefined traditional printing methods through software innovation, harnessing one of the largest digital press footprints globally, and utilizing the most advanced laser finishing lines, which produce over 500,000 square feet daily.

Labels: 48-Hour Turnarounds

Enables A/B Testing

Eliminate Lead Times

Vary Label Designs

Free up Capital

Eliminate Bulk Orders

Eliminate Miscounts

Eliminate Inventory

Streamline Procurement

Free Up Floor Space

Supply Chain Visibility

Reduces Waste, Energy, & Emissions

48-hour Label turnarounds

Change the Game!

Eliminating:

We have set a new industry standard while reducing environmental impact. Join us and set your brand apart.

Better. Faster. Cheaper.

Inventory: From 90 Days to 7 Days - Saves 25%

One of our clients was bulk ordering 90 days of inventory to combat inconsistent and, at best, 4-week lead times and to gain a better price. Now, they’re only ordering what is needed for the following week’s production schedule, saving time on inventory management, reducing the risk of label damage or loss, reclaiming floor space, and freeing up capital. Total cost reduction = 60%!

Better. Faster. Cheaper.

Order What You Need, When You Need It

Change your procurement strategy, reduce risks, and order only what is needed for current production. No more excess inventory, and lower costs!

With a standard 48-hour turnaround and at the same low price as a bulk order, why order more than you need?

The Future is Here: On Demand Labels

Imagine placing an order and having it shipped in just 48 hours.

We’ve defied industry norms—a game-changer for procurement strategies.

Order what you need for your current production; no more costly bulk orders!

Imagine the new flexibilities: A/B test labels for market fit or vary label designs to engage consumers better without the cost and lead time constraints.

Welcome to the future.

Better. Faster. Cheaper.

72-Hour Large-Format Turnaround: Offline meets Online

Have long lead times prevented you from synching online campaigns with brick-and-mortar?

We printed and shipped a 2,000 retail store refresh in 72 hours!

Say hello to the future where online and brick-and-mortar worlds merge into one, enabling new flexibilities to power your brand.

The future is now here. Marketers dream no more.

Welcome to the future.

Better. Faster. Cheaper.

Inventory: A Four-Letter Word?

The future does not know the concept of excess inventory. That future is now.

48-hour On-Demand label turnarounds enable you to order the quantity needed to meet your current production schedule.

Procurement leaders need to rethink label procurement strategies to save on TOTAL costs, not just unit costs.

Don’t show your age by carrying excess label inventory.

Welcome to the future.

Better. Faster. Cheaper.

LabelDrive: On-Demand.

An industry-changing 48-hour on-demand turnaround with no minimum order quantities or pricing tiers that disadvantage small brands. Order only what is needed for current production, eliminating excess inventory and the risks of obsolete, lost, or damaged labels.

Labels, Stickers, Decals

- On-Demand 48-Hour Turnaround

- No MOQs & Flat Pricing

- No Setup Fees

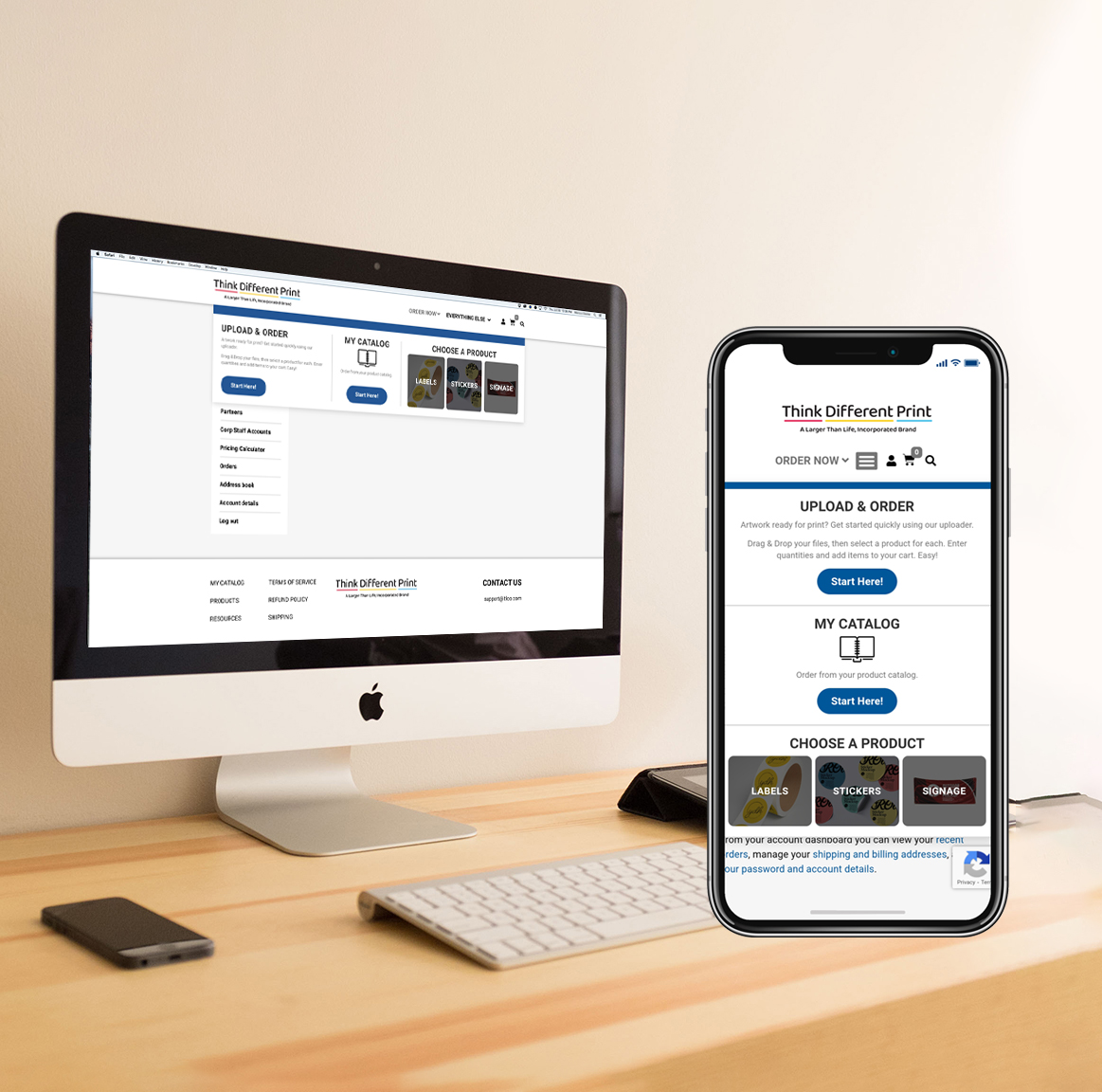

- Branded Order Catalogs & Label Management Platform

Large-Format: Store Graphics

- 72-Hour Turnaround

- Wholesale Price

- Branded Ordering Catalogs

Better. Faster. Cheaper.

LabelDrive: Centralize Procurement, Reduce Costs

We offer private-label manufacturers a predictable, flexible on-demand centralized procurement model to streamline and lower costs for their brands and customers.

Program Features:

- 48-Hour Standard Turnaround

- No MOQs with Flat Pricing

- No Set Up Fees

- Online Ordering and Label Management Platform

Benefits:

- Reduce Costs by 70%

- Flexible Procurement

- Predictable Lead Times

- Eliminate Excess Inventory

LabelDrive Plus: Offer LabelDrive Benefits to Your Customers!

No matter what your procurement model, LabelDrive PLUS’ white-label reseller platform centralizes procurement across your brands and customers and helps you scale.

- Reduce costs by 70%

- New Revenue stream

- Gain Procurement Control

- Gain Supply Chain Visibility

- Create Competitive Advantage to Win More Deals

Better. Faster. Cheaper.

Franchise Print Hub: Your Franchise Our Focus

Revolutionize your franchise’s print needs with our new centralized print portal solutions. Experience the power of streamlined efficiency, massive cost savings, and unwavering brand consistency, all while unlocking a new revenue stream.

Program Features:

- Ordering Portal & Label Management Platform

- Wholesale Price Structure

- Rapid Turnarounds

- No Setup Fees

Benefits:

- Control Brand Consistency

- Reduce Costs & Save Time

- Increase Efficiency and Peace of Mind

- New Revenue Stream

Read more about how Franchise Print Hub is helping franchises.

Better. Faster. Cheaper.

Your Challenge is Our Blueprint

for Innovation

At the heart of our operations is a philosophy:

Every challenge a customer faces is a challenge we embrace. It’s an opportunity. It makes us better. Our dedication to automating and streamlining touchpoints ensures not only a hassle-free experience but also constant innovation, driven by your feedback. Stay informed, stay ahead, and most importantly, stay excited about your orders.

What is your challenge?

Better. Faster. Cheaper.

Connect

More than just a label printer

At Think Different Print, we dedicate time to assist you with all your printing needs, saving you both time and money.

Check out our CAPABILITIES to learn more!

- Labels

- Stickers

- Decals

- Store Graphics

- Posters

- Window Perf

- Banners

- Signs

- Fleet wraps

- Stadiums Wraps

- Building Wraps

- Etc.

High Quality, Fast & Affordable

Case Studies

From Vendor to Strategic Partnerships

Transforming Customer Challenges Into A Blueprint of Innovation.

From 6 Weeks to 3 Days: Large Fashion Retail Chain

Problem: – A six-week lead time for store graphics led to a lack of consistency between their 800+ retail locations and their digital presence, causing a non-uniform customer experience

Solution: – Our “paperless factory” operations, software innovation, and state-of-the-art equipment enable us to produce their store graphics within 3 days.

Result: – Customers enjoy a uniform online & store experience. The retailer can now A/B test with rapid turnaround.

Better. Faster. Cheaper.

Ad Campaign Visualization - Large Global Brands

Problem: – A client was losing large-scale media buys because their clients could not visualize advertising campaigns in a large NYC subway station.

Solution: – We created Ad Space 360 which provides 3D renderings of the subway stations and catalogs all of the ad spaces.

Result: – The client never lost another client for subway station media buys.

Better. Faster. Cheaper.

Label Inventory - 90 days to 7 days

Problem: – Long lead times (4 weeks at best) and better unit price points forced a client to bulk buy labels. This set up exposure to higher TOTAL COSTs; loss, damage, obsolescence, tied-up capital, and floor space.

Solution: – With a standard 48-hour turnaround. They carry stock for a 1-week production schedule.

Result: – They realized a 10% label savings due to label loss, damage, and obsolescence. 200% less tied-up capital in inventory and freed up floor space for a new office.

Better. Faster. Cheaper.

Environment. Sustainability

Problem: – Eliminate toxins in materials to meet ESG concerns

Solution: – Developing technology to remove PVC from the industry, creating water-based adhesives as well as the ability to recycle PVC.

Results: – Our clients can demonstrate to their customers their commitment to the environment.

Better. Faster. Cheaper.

Join Us on This

Revolutionary Journey!

Embrace the future of printing. Be the future. Experience unparalleled service, quality, and innovation with Think Different Print. Dive into our portfolio, watch our processes in action, and get a quote and branded samples today!